It is generally respected by the industry that if you need a substrate covered in something you should look to use a plasma spray or electroplating techniques. The protection and longevity offered by a coating of some kind is considered to be essential to the longlife and cost savings in terms of the product. This is especially true if the product is to be exposed to extreme elements or high and low temperatures.

The company of https://www.poeton.co.uk/standard-treatments/plasma-coatings are one of the best in being able to advise and direct you in what you need in terms of a Plasma polymer composite . They have the full range of facilities to complete the job including the use of Plasma spray guns.

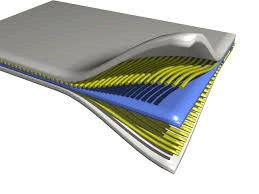

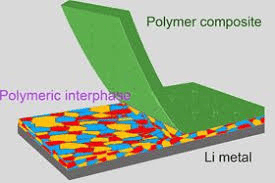

What goes into the polymer composite? As the name composite suggests, a variety of materials are added together that all make up a protective coating you can trust. One of the most comprehensive elements is Nickel sulfate. Nickel is a metal that is rust and tarnish resistant plus it is very hard wearing. Polymers are plastic fibres that are combined with chemicals (such as the Nickel sulfate) to make a tight plastic bond. This polymer is fluid, as it can melted down to molten levels, then fired at the substrate. It then sets hard, permanently, around the substrates.