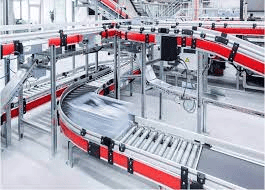

When talking about conveyor belts, we firstly have to define it so that we can understand its importance as a part of the manufacturing process. A traditional belt is made up of an array of pulleys that are fitted to a large drum or cylinder. The belts are controlled by a larger drum or cylinder, which is used to pull or push the belts through the holes they are supposed to go through. The belt is then connected to a trolley or dolly, which is used to transport the items that need to be moved along the belt, to the job or storage area. There are different types of conveying systems, such as pneumatic and vacuum.

Keeping your belt in good working condition is therefore very important, because if the belt is not maintained properly, then you will have to replace the entire drum, belt and even the trolley or dolly along with the entire belt assembly, which will cost you a lot of money. Therefore, it is always better to spend money on the maintenance of your belt, than on the replacement of items. There are many companies which offer belt inspection services, which help you identify the problems that may develop over time. The inspection report will also tell you the possibility of any major problems developing, and how much it will cost you to repair the damage. For Vacuum Conveying, visit Aptech, a leading Vacuum Conveying company.

The importance of belt inspection is highly evident in manufacturing plants where the belts are used for a lengthy period of time. If the belts are not well maintained, then it will lead to premature wearing of the belt. There are chances that belts can develop problems like friction, heat and rust etc.